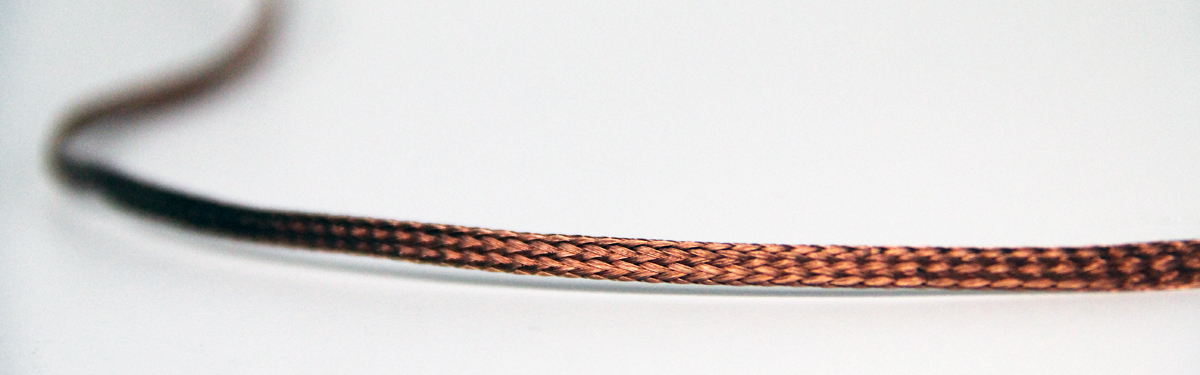

Flat Copper Braid

Flat copper braid from Arcor Electronics is made from bare tinned copper and is used for many different things. Copper braid is suitable for ground wire applications and can either carry an electric current or ground an electrical device. Flat copper braid is used in wiring applications where no insulation is needed.

Types of Braided Wire

Braided wire can be provided rolled flat or in tubular form. Flat braids –including flat copper braid—are generally used for flexible connections, electrical leads, and grounding straps, while tubular braids are used to shield EMI and ARA static.

At Arcor Electronics, our standard put ups are 100, 250, 500, and 1,000 feet; however, special sizes and put ups for flat copper braid are available on special order. Our braided copper wire is resistant to failure from flexing, making it ideal for applications where flexibility is called for.

When to Use Flat Copper Braid

Braid is, as mentioned, the wire of choice when flexibility is required. It’s sometimes used for electrically bonding parts of a vehicle, such as an exhaust pipe, door, or hood. It is also good for bonding swinging gates and doors to a grounding system. It provides a low resistance ground path and is an ideal shielding material for short-run cables.

To learn more about the braided copper wire, including flat copper braid, that is available from Arcor Electronics, contact us today.

| ARCOR TINNED COPPER | ARCOR BARE COPPER | NOM. I.D. WHEN ROUNDED | AWG. OF INDIV ENDS | NO. OF STRANDS (CARRIER) | NO. OF WIRES PER STRAND | TOTAL NO. OF INDIV. WIRES | APPROX. AWG. EQUIV. | NOMINAL CIRCULAR MILLS | CURRENT CARRYING CAPACITY (AMPS) | APPROX. SHIPPING WEIGHT LBS. |

|---|---|---|---|---|---|---|---|---|---|---|

| USB1/32 | UMB1/32 | 1/32″ | 36 | 24 | 1 | 24 | 22 | 600 | 7 | 5 |

| USB1/16 | UMB1/16 | 1/16″ | 36 | 24 | 2 | 48 | 19 | 1200 | 11 | 7 |

| USB5/64 | UMB5/64 | 5/64″ | 36 | 24 | 3 | 72 | 18 | 1800 | 16 | 9 |

| USB7/64 | UMB7/64 | 7/64″ | 36 | 24 | 4 | 96 | 16 | 2400 | 19 | 11 |

| USB1/8 | UMB1/8 | 1/8″ | 36 | 24 | 5 | 120 | 15 | 3000 | 25 | 13 |

| USB5/32 | UMB5/32 | 5/32″ | 36 | 24 | 10 | 240 | 12 | 6000 | 40 | 24 |

| USB11/64 | UMB11/64 | 11/64″ | 36 | 24 | 7 | 168 | 14 | 4200 | 32 | 17 |

| USB13/64 | UMB13/64 | 13/64″ | 34 | 24 | 8 | 192 | 11 | 7630 | 46 | 31 |

| USB13/64 | UMB13/64 | 13/64″ | 36 | 24 | 13 | 312 | 11 | 7800 | 46 | 31 |

| USB1/4 | UMB1/4 | 1/4″ | 36 | 24 | 16 | 384 | 10 | 9600 | 53 | 38 |

| USB9/32 | UMB9/32 | 9/32″ | 30 | 24 | 5 | 120 | 9 | 12060 | 60 | 47 |

| USB3/8 | UMB3/8 | 3/8″ | 30 | 24 | 7 | 168 | 8 | 16880 | 75 | 62 |

| USB3/8 | UMB3/8 | 3/8″ | 36 | 48 | 8 | 384 | 10 | 9600 | 53 | 40 |

| USB7/16 | UMB7/16 | 7/16″ | 30 | 24 | 10 | 240 | 6 | 24120 | 90 | 85 |

| USB1/2 | UMB1/2 | 1/2″ | 30 | 24 | 15 | 360 | 5 | 36180 | 120 | 122 |

| USB1/2 | UMB1/2 | 1/2″ | 36 | 48 | 11 | 528 | 9 | 13200 | 62 | 53 |

| USB9/16 | UMB9/16 | 9/16″ | 30 | 48 | 10 | 480 | 3 | 48240 | 145 | 156 |

| USB21/32 | UMB21/32 | 21/32″ | 30 | 48 | 16 | 768 | 1 | 77180 | 190 | 259 |

| USB25/32 | UMB25/32 | 25/32″ | 36 | 48 | 18 | 864 | 7 | 21600 | 88 | 79 |

| USB7/8 | UMB7/8 | 7/8″ | 30 | 48 | 7 | 336 | 5 | 33770 | 100 | 123 |

| USB1.0 | UMB1.0 | 1″ | 30 | 48 | 8 | 384 | 4 | 38600 | 120 | 140 |

| USB1-1/8 | UMB1-1/8 | 1 1/8″ | 30 | 48 | 9 | 432 | 4 | 43420 | 130 | 155 |

| USB1-1/4 | UMB1-1/4 | 1 1/4″ | 30 | 48 | 10 | 480 | 3 | 48240 | 145 | 168 |

| USB1-3/8 | UMB1-3/8 | 1 3/8″ | 30 | 48 | 11 | 528 | 3 | 53060 | 145 | 185 |

| USB1-1/2 | UMB1-1/2 | 1 1/2″ | 30 | 48 | 12 | 576 | 3 | 57890 | 145 | 200 |

| USB2.0 | UMB2.0 | 2″ | 30 | 48 | 14 | 672 | 2 | 67540 | 180 | 230 |

| USB2-1/4 | UMB2-1/4 | 2 1/4″ | 30 | 48 | 16 | 768 | 1 | 77180 | 190 | 260 |

Use the following chart to help you select what size flat copper braid is required. You can select the Arcor item number by AMPACITY or AWG, then refer to presentation by dimensions chart.

| CURRENT CARRYING CAPACITY (AMPS) | ARCOR BARE COPPER | ARCOR TINNED COPPER | APPROX AWG. EQUIV. | APPROX AWG. EQUIV. | ARCOR BARE COPPER | ARCOR TINNED COPPER | CURRENT CARRYING CAPACITY (AMPS) | |

|---|---|---|---|---|---|---|---|---|

| 93 | UPB1/2 | UQB1/2 | 6 | 1 | UPB1-1/2 | UQB1-1/2 | 180 | |

| 93 | UPB3/4 | UQB3/4 | 6 | 1 | UPB1.0 | UQB1.0 | 195 | |

| 100 | UPB1-3/8 | UQB1-3/8 | 5 | 1 | UPB1-5/8 | UQB1-5/8 | 200 | |

| 120 | UPB5/8 | UQB5/8 | 5 | 2 | UPB7/8 | UQB7/8 | 150 | |

| 120 | UPB1.0 | UQB1.0 | 4 | 2 | UPB1-3/8 | UQB1-3/8 | 165 | |

| 145 | UPB3/4 | UQB3/4 | 3 | 2 | UPB15/6 | UQB15/6 | 170 | |

| 145 | UPB1-1/4 | UQB1-1/4 | 3 | 2 | UPB15/6 | UQB15/6 | 175 | |

| 145 | UPB1-1/2 | UQB1-1/2 | 3 | 3 | UPB3/4 | UQB3/4 | 145 | |

| 150 | UPB7/8 | UQB7/8 | 2 | 3 | UPB1-1/4 | UQB1-1/4 | 145 | |

| 165 | UPB7/8 | UQB7/8 | 3 | 3 | UPB1-1/2 | UQB1-1/2 | 145 | |

| 165 | UPB1-3/8 | UQB1-3/8 | 2 | 3 | UPB7/8 | UQB7/8 | 165 | |

| 170 | UPB15/6 | UQB15/6 | 2 | 4 | UPB1.0 | UQB1.0 | 120 | |

| 175 | UPB15/6 | UQB15/6 | 2 | 5 | UPB1-3/8 | UQB1-3/8 | 100 | |

| 180 | UPB1-1/2 | UQB1-1/2 | 1 | 5 | UPB5/8 | UQB5/8 | 120 | |

| 195 | UPB1.0 | UQB1.0 | 1 | 6 | UPB1/2 | UQB1/2 | 93 | |

| 200 | UPB1-5/8 | UQB1-5/8 | 1 | 6 | UPB3/4 | UQB3/4 | 93 | |

| 235 | UPB1-3/8 | UQB1-3/8 | 1/0 | 1/0 | UPB1-3/8 | UQB1-3/8 | 235 | |

| 250 | UPB1-3/4 | UQB1-3/4 | 2/0 | 2/0 | UPB1-3/4 | UQB1-3/4 | 250 | |

| 255 | UPB2.0 | UQB2.0 | 2/0 | 2/0 | UPB2.0 | UQB2.0 | 255 | |

| 290 | UPB2.0 | UQB2.0 | 3/0 | 3/0 | UPB2.0 | UQB2.0 | 290 | |

| 320 | UPB2.0 | UQB2.0 | 3/0 | 3/0 | UPB2.0 | UQB2.0 | 320 | |

| 370 | UPB2-3/8 | UQB2-3/8 | 4/0 | 4/0 | UPB2-3/8 | UQB2-3/8 | 370 | |

| 390 | UPB3.0 | UQB3.0 | 4/0 | 4/0 | UPB3.0 | UQB3.0 | 390 | |

| 410 | UPB2-1/2 | UQB2-1/2 | 250 MCM | 250 MCM | UPB2-1/2 | UQB2-1/2 | 410 |